Development & production

Simulation and production of naval propulsion

Castings

We have 2 electric induction furnaces that provide us with a capacity of 10 tons of finished piece.

Chemical and mechanical characteristics required for the melt are guaranteed by our strict laboratory control material during the casting process and subsequent testing of specimens obtained from each casting.

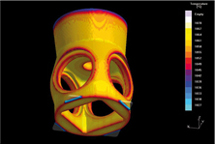

The casting process is designed from our engineering process through simulation programs that enhance and direct the work shop.

Our new sand reclamation plant ensures maximum efficiency and speed of release and reprocessing of sand at the same time contributing to the goal of developing our procedures with minimal ecological impact and maximum commitment to sustainable development.

Mechanising anf Finishing

The machining is performed by numerically controlled milling machines, with particular emphasis on machining the entire surface of propellers and blades to even the foot, through programs developed individually for each piece. We can machine Φ blades up to 3m. high

In the grinding phase takes place the finished pieces and a static balancing scanned in two planes to ensure maximum accuracy.

Smelting and pouring in the cast

Full Simulation

Complete mechanising in CNC machines

Verification in all process phases

Great quality finish

Perfect packing for transportation

Polígono Industrial "El Bosque", parc. 6

Polígono Industrial "El Bosque", parc. 639716 Entrambasaguas (CANTABRIA)

Phone: (+34) 942 523 892 - Fax: (+34) 942 523 893

info@casusopropellers.com

GBR

GBR